What is a pneumatic cylinder? What are the types of pneumatic cylinder||Double acting u0026single acting

#What are pneumatic cylinders and what is the function of a pneumatic cylinder

A pneumatic cylinder is also called a pneumatic actuator is a device that is used in industrial automation applications to provide motion and force. A pneumatic cylinder uses compressed air to create force. This device is widely used in automated systems, machines, and processes. Movement of the products is done directly or indirectly by the pneumatic cylinder and the load will be moved by pushing, pulling, etc. These devices are not costly and can be installed easily. This device can create a huge amount of force over a board range of velocities without overheating or internal damage. Its operation is not affected by its environmental conditions like it can be used in dusty and high humidity locations.

How does a pneumatic cylinder work

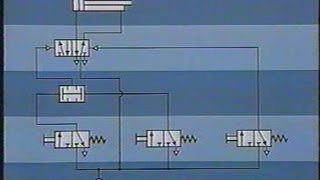

A pneumatic cylinder uses compressed air for its operation it is a linear actuator. The compressed air will be converted into kinetic energy or it can also be described as the conversion of potential energy into kinetic energy. This kinetic energy is used in the loads to move it. So when the compressed air is converted into kinetic energy the air will expand so that it can reach the atmospheric pressure. The piston in the cylinder is forced by the expanded air in the desired direction. The piston is mostly a disc or cylinder, and the piston rod will transfer the generated force to the object that is to be moved.

What are the types of a pneumatic cylinder and how does it work

Singleacting cylinders

This device uses the pressure imparted by the compressed air to create a driving force in one direction and it would return back to its position with the help of a spring. The extension of this cylinder is limited because of the space that the compressed spring uses. This device has another disadvantage that it would lose some force when it tries to push the spring and because of this, the singleacting cylinders are not used in applications where high force is required.

What are the advantages of a singleacting cylinder

Defined position in the event of power failure

Reduced air consumption

Easy actuation

What are the disadvantages of a singleacting cylinder

The construction length of the cylinder is long

Force is built up in one direction

#No constant force

#Force will be reduced by the spring force

#Doubleacting cylinders

#pneumatic cylinder#

}

pneumatic cylinder

pneumatic cylinder force calculator

pneumatic cylinder kit

pneumatic cylinder explosion

pneumatic cylinder diagram

pneumatic cylinder types

pneumatic cylinder parts

pneumatic cylinder force chart

pneumatic cylinder 24 inch stroke

pneumatic cylinders and couplers

pneumatic cylinder project

pneumatic cylinder position control

#pneumatic cylinder basics#

pneumatic cylinder repair

pneumatic cylinder arduino

pneumatic cylinder speed control

#pneumatic cylinder control

#pneumatic cylinder press

#pneumatic cylinder working animation#

#pneumatic cylinder assembly#

#pneumatic cylinder uses#

#pneumatic cylinder animatronic

#pneumatic cylinder position sensor

#what is difference between hydraulic cylinder and

#what is the difference between hydraulic and pneum

#4 examples of a pneumatic device

#what does a pneumatic cylinder do in autos

how pneumatic press works

what physical property is a pneumatic system based

pneumatic cylinder

pneumatic cylinder

pneumatic cylinder parts

pneumatic cylinder calculator

pneumatic cylinder force calculator

pneumatic cylinder force

pneumatic cylinder pdf

pneumatic cylinder stroke

Doubleacting cylinders uses the force of the compressed air to move the rod, this type has a piston rod and this piston rod does the transfer of compressed air to the load. There is also a cushioning piston at the rod end and it won’t allow any hard shocks at the end of the stroke, this is done by stopping the piston slowly and gently. There is an airtight seal between the piston and the rod piston and it is achieved by a static seal. Metal to metal contact of the piston and the cylinder is prevented with the help of a piston guide ring. There are airports in both ends of the cylinder and through these airports the compressed air will flow in and out of the cylinder. The piston will move away from the cylinder during the extension stroke and comes back during the retraction stroke and this is achieved by the compressed air and this way it moves the load.

What are the advantages of doubleacting cylinders

Constant force

Force can be built in both side of the direction

Strokes of several meters can be achieved

What are the disadvantages of doubleacting cylinders