What is a Spool Valve?

▶ C'mon over to https://realpars.com where you can learn PLC programming faster and easier than you ever thought possible!

=============================

▶ Check out the full blog post over at

https://realpars.com/spoolvalve/

=============================

Spool valves are found in almost every industry you can imagine performing a wide range of tasks.

Spool valves can be used in both hydraulics (where oil is the energy source) or Pneumatics (where the air is the energy source) and their job is to control the flow direction of the energy source by combining or switching the paths through which the oil or air can travel.

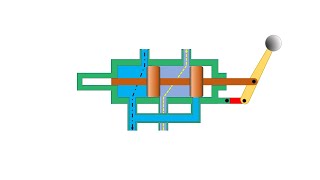

Essentially a spool valve is a cylinder inside a sealed outer case.

There are several chambers drilled through the case from one side to the other; these are commonly known as ports.

A spool valve can be operated in a number of ways, we could use a button, a lever or by way of a solenoid.

Whatever the method is chosen to control the valve, all that we are doing is simply pushing the spool to move within the housing, and by doing this we are allowing or blocking the path between the ports.

In some cases, there may be a solenoid at each end of the valve, whereas in others there is a spring return so when the solenoid is no longer pushing the actuator the spring will return the spool to its “normal” or rest position.

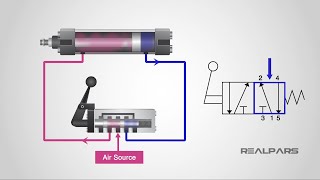

Imagine the example of extending a pneumatic cylinder using a spool valve.

The Pneumatic air supply is connected to the inlet port 1.

Port 2 is connected to the pneumatic cylinder extend connection.

Port 3 is unconnected as it is the exhaust port.

In the normal state without the actuator being operated nothing will happen as the spool is physically blocking the airflow at port 1 and the cylinder is retraced because ports 2 and 3 are connected due to the spool position.

So any air already within the system would escape to the atmosphere through the exhaust port. Let’s consider this the “normal” or rest position.

Now imagine we operate the actuator. We would see the spool position changes and the cylinder extends.

This is because the spool has moved position unblocking port 1 and simultaneously blocking port 3 resulting in allowing airflow from port 1 to port 2 while blocking the exhaust.

This is known as our working position.

The cylinder will remain extended until the spool is moved back to the normal position, either by way of another actuator at the opposite end of the valve or by an internal spring return.

In our example, this type of valve would be known as a 3/2 valve because we have 3 ports and 2 spool positions.

Spool valves are usually referred to by the nomenclature 3/2 or 5/3 etc., where the first number relates to the number of ports and the second to the number of different spool positions.

The blocking parts of the spool are known as “lands”, which are raised above the spool core; if these are made different in configurations they can change the way the port pathways interconnect.

=============================

Missed our most recent videos? Watch them here:

https://realpars.com/uninterruptible...

https://realpars.com/firealarmsystem/

https://realpars.com/iprating/

=============================

To stay up to date with our last videos and more lessons, make sure to subscribe to this YouTube channel:

http://goo.gl/Y6DRiN

=============================

TWEET THIS VIDEO https://ctt.ac/3aKSk

=============================

Like us on Facebook: / therealpars

Follow us on Twitter: / realpars

Follow us on LinkedIn / realpars

Follow us on Instagram / realparsdotcom

#RealPars #automation #SpoolValve