Single Acting and Double Acting hydraulic cylinders: What's the difference?

In this video, we will explain the difference between a single acting hydraulic cylinder and a double acting hydraulic cylinder.

Find out more at https://sarumhydraulics.co.uk/'>https://sarumhydraulics.co.uk/

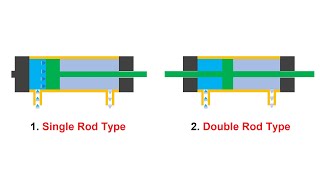

A single acting cylinder has a piston rod, a cylinder barrel, a hydraulic seal and normally a bearing to limit how far it pumps out.

When you feed oil or your hydraulic fluid into it through the inlet port, it will extend, exerting a force. In this case, lifting a mass. In this example we’re using a Micropac hand pump to provide the pressurised fluid. Hand pumps are low tech and easy but you could alternatively use an electric pump or air driven pump.

When it has done its work, you need to release the fluid back into the tank. To do this we’ve fitted a needle valve into the Micropac hand pump. You open the valve and the oil flows,letting the mass drop.

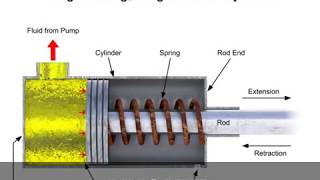

You always need a way of returning the cylinder. Either gravity return or use a spring.

So the single acting cylinder will pump out, doing its work and retract when the fluid is released back into the tank. In and out.

A double acting cylinder will allow you to push and pull under hydraulic power. You’ve got a similar piston rod with a seal on the piston. You have a cylinder barrel and a piston rod bearing with an extra seal. This forms a second hydraulic chamber.

You’ll need a four way directional control valve to operate your double acting cylinder. We’ve added one to our Micropac pump.

There are two connections on this valve, one at either end of the cylinder.

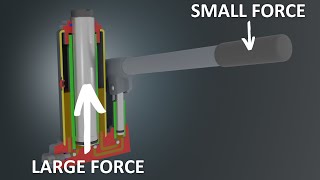

Pressurise the bottom of the ram or full bore end to generate force. You need to connect the upper chamber, or reduced bore, to the tank or the ram will jam. The oil has to go somewhere.

You can see the ram is now extending. At the end of the stroke, we are reversing the four way valve so the pressure feed is now connected to the reduced bore end. We can now retract the ram under power and pull the rod back. It doesn’t need a spring or gravity to return it.

The force generated by the hydraulics will be smaller because the area is smaller.

Now you’ve seen single and double acting hydraulic cylinders, or hydraulic rams, in action. A simpler single acting cylinder that needs gravity return and the more complex double acting ram that provides force in both directions.

At Sarum Hydraulics, we supply Micropac manual pumps to operate single and double acting cylinders. And as the hand pump experts, we’ve got solutions for a wide range of demanding applications.

Talk to us today or find our more at https://sarumhydraulics.co.uk/'>https://sarumhydraulics.co.uk/