What’s the difference between a single-speed and a two-speed hydraulic hand pump?

In this video, we tell you how to decide whether you need a singlespeed or a

twospeed hydraulic hand pump for your job.

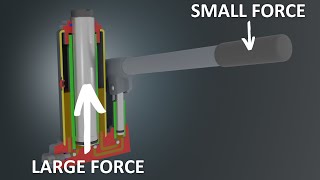

A singlespeed hand pump is very simple, it is low cost and there are a lot on the market. A singlespeed pump has a maximum working pressure, normally set to the highest load that the person operating the pump can safely exert. The higher the load that they put on the pump, the higher the pressure.

Let's show a singlespeed hand pump connected to a simple hydraulic press using a singleacting cylinder. In this example, we're going to crush a tin can. Notice that when the operator starts pumping, the cylinder moves down by the same amount each stroke. This is because the amount of oil displaced per stroke is always the same. Until the cylinder reaches the can, the handle load is very low and very little pressure is needed, however, the operator must still pump a full stroke each time. Once the cylinder finally reaches the can the pressure starts to rise. The handle load increases and this continues until the can is crushed and the operator cannot exert any more force. They have reached the maximum working pressure. So now let's look at a twospeed hand pump.

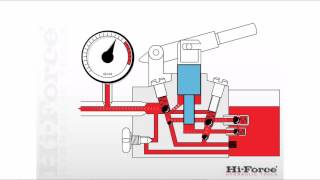

A twospeed hand pump has the ability to switch from a highdisplacement, lowpressure stage, to a lowdisplacement, highpressure stage. Let's connect a twospeed hand pump to the same cylinder, crushing another tin can. To begin, the pump is set on the lowpressure stage. Watch how the cylinder travels a greater distance each stroke, reaching the tin can much more quickly. When the cylinder reaches the tin can, the operator switches to the highpressure stage. See how the cylinder

now travels a smaller distance. The can is crushed, reaching the same maximum operating pressure.

So there you have a singlespeed and a twospeed hydraulic hand pump. In this example, the twospeed pump has clear benefits. At the start where there is low pressure but a significant distance for the cylinder to travel, less strokes are needed, making it quicker than the singlespeed pump. At the end, by switching to the highpressure stage, the handle load can be optimized for easy

operation.

Lots of hydraulic jobs require high displacement at low pressure before the

hard work starts. For example ball valve actuators, pressure testing, charging and filling, presses, and so on.

Some applications are high pressure all the way so a twospeed hand pump isn't the right option for the job. Cranes, patient lifts, hospital beds, hatches, and some types of valves with hydraulic actuators, to name a few...

If you're unsure about which type of hand pump is right for your application, talk to us or comment below.

Micropac hand pumps are available as both singlespeed and twospeed units, and, as the hand pump experts, we've got solutions for a wide range of demanding applications. Talk to us today, comment below, or find out more sarumhydraulics.co.uk