How to set up a TacticalFlowMeter Series VT-222 Multivariable Vortex Flow Meter.

https://www.tacticalflowmeter.com/pro...

How to set up a TacticalFlowMeter Series VT222 Multivariable Vortex Flow Meter.

There are THREE buttons on the front of the Vortex Meter Display .

Left Click to change screens and when the Password shows up LONG hold the Right Button to invoke the input and use the Left button to advance the number to 2 and when that is in use the Right button to move to the second digit and advance with the Left button to the number 2. When you see 22 LONG hold the Right button and you are in the edit mode.

Call (831)2448080 for questions

Electronics Specifications

Power Supply: 1232VDC

Operating Temperature: 20°C to 70°C(with LCD 40°C to 85°C(without LCD)

Output: 420mA output

Configuration: Flow mode, Flow unit, Range (Qmax), Density, Temperature, etc.

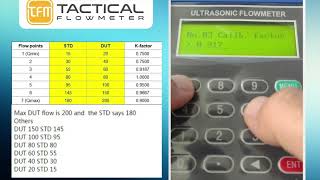

Alarm: Low alarm outputs 3.8 mA & high alarm can outputKFactor linearity: The VT222 provides 2 to 5 points of KFactor linearity correction.

Local adjustments: Setting range and PV units, Density, Flow mode, damping, high alarm percent, low alarm percent and data recovery etc.

LCD display: Line 1 shows the instantaneous flow. Line 2 shows the totalized flow. Line 3 can display the percentage, output current, temperature, pressure, density and more combinations easily selected by the user.

Multivariable Operation:The VT222 supports realtime temperature and pressure compensation for gas, and utilizes the international standard for the steam and density tables for temperature and pressure compensation as well for superheated steam with pressure compensation or temperature compensation for saturated steam.

Temperature trim: High trim and low trim .

Pressure trim: High trim and low trim .

The VT222 provides powerdown protection and flow totalizer value storage functions.

Enter or Exit Menu Mode

Enter Menu Mode

In the operating mode, press the "E" key to Enter the menu mode (data entry).

Exit Menu Mode

In the menu mode, press the "E" key to Exit the menu mode and Enter the operating mode.

Data Entry Method

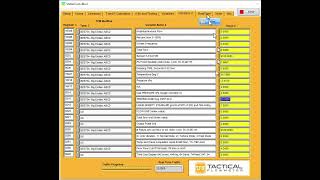

There are two ways to set parameters, one is using the "Keypad Method" with the3 button interface on the

electronics and the other way is to use ModBus to set the parameters. To make it easier be sure to watch the videos

on the website that demonstrates the methods clearly.

‘Keypad’ Method

Long press the DKey to enter the setting, and the sign flag will start flashing.

Short press the DKey to select the sign.

Press the UKey to shift the setting number. The number bit will start flashing, which means that

you can set. Press DKey to increase the setting number.

Press the UKey to shift the setting number again. All digits can be set using the same method.

After setting all 6digits, press UKey to set the decimal point position. All five decimal points will flash simultaneously, indicating they can be set. Short press DKey to change the decimal point position.

After completing data entry, you can long press DKey to save the parameters. Or Press E Key to abort and exit. The D and E Keys are important to select based on your needs. Long hold the DKey to save your changes.

For example, On the next pages we show changing the Full Scale from 200, the new input range limit of 400. Setting the range limit, Full Scale, is important for driving the 420 mA and Frequency Outputs.

Long press DKey to enter settings, and the menu options will start flashing.

Short press DKey or SKey to scroll backward or forward in the menu.

Long press DKey to access, and then save, the parameter.

Vortex Meter Velocity Ranges:

The Vortex meter has different minimum and maximum flow velocities it can measure based on the fluid type and meter size. Please note the values below for proper sizing of your meter.

• Steam:

1/2” ANSI Flange: 470m/s or 78713,800 f/m or 13230 f/s

1” ANSI Flange: 370m/s or 590 13,800 f/m or 9.8230 f/s

2” to 12” ANSI Flange: 1.570m/s or 30.213,800 f/m or 4.92230 f/s

• Gas:

1/2” ANSI Flange: 465m/s or 78712,790 f/m or 13 213 f/s

1” ANSI Flange: 365m/s or 59012, 790 f/m or 9.8 213 f/s

2” to 12” ANSI Flange: 1.565m/s or 300 12,790 f/m or 4.9213 f/s

• Liquid:

1/2” to 12” ANSI Flange: 0.210m/s or 40 1,968 f/m or .6632.8 f/s

View full spec sheet here.

https://www.tacticalflowmeter.com/pro...

Please subscribe to our channel and hit LIKE if this video helped you.