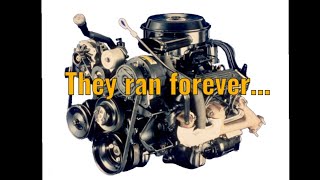

HD Ford 300 build Part 2

Part 2...

Second part in the HD Ford 300 build. This video doesn't have much "build" in it but more of the mundane parts of building any engine. grinding, painting, pretty'ing up things with basic hand tools, and using the original hardware.

Some of the segments seem out of order because of all the issues I have had with it. The engine has been sealed up for some time with some of the sheet metal/outer covers etc., so I have had to disassemble it a time or two depending on what I wanted to accomplish that day. The deck has been surfaced twice due to an accident that blemished it after it had been surfaced already, but no biggie it helped me get closer to the deck tolerances that I was looking for.

Had to fix (or try) the timing cover as it was cracked, it probably would have been fine but I just had to!

An oil passage plug was cracked in the side of the block adjacent to the timing cover, it was seized in good so after stripping it out I had to drill and tap/clean the threads. 1/16" NPT if anyone needs to know.

All in all it has been going together slow and with many interruptions. The largest obstacle so far is I am terrible at video editing, but hopefully that will change in the future. On that note if anyone has any recommendations on a decent, simple, well rounded video editor I would be interested in what you have to say!

This build has changed quite a bit since I originally started it and I'm not exactly certain where it is going still! I may in the future swap the rods and pistons out again for forged so.. Not sure at this point. If I do i will of course have a video, but at this point I am looking at getting it together and firing it up within the next 4 months. The new pistons currently are a 15.78 CC dish, i will spec and CC them out at a later date/video.

Most of the engine specs are listed in the description on part 1.

~Still to do:

Mill the 240 head rocker stud bases and CC the chambers to get a better grasp on my compression ratio. As of now I have roughly calculated it @ 9.4:1 which is fine for what I want out of this engine, .... at this time :)

Thanks again, more to come...