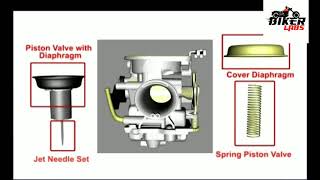

This is how Carb Diaphragms Actually Work

A compact twostroke chainsaw carburetor's metering diaphragm and fuel pump diaphragm play key roles in ensuring that the engine receives the proper air and fuel ratio for effective combustion. Let's investigate how these diaphragms work:

Fuel Pump Diaphragm: The fuel pump diaphragm is frequently the first part in the fuel circuit of the carburetor. gasoline delivery from the gasoline tank to the carburetor and then the engine is its main duty. The fuel pump diaphragm depends on pressure changes brought on by the engine's cycles to function.

This is how it goes:

Crankcase Pressure Pulses: As the engine operates, the crankcase experiences pressure pulses. During the intake and exhaust strokes of the engine, the piston moves and the volume of the crankcase changes, causing these pulses.

Impulse Line: The crankcase and carburetor are connected by an impulse line, which is how these crankcase pressure pulses are communicated. The carburetor receives the pressure changes through this connection.

Diaphragm Flexing: The gasoline pump diaphragm in the carburetor flexes when pressure pulses from the crankcase reach it. Fuel is pumped from the fuel tank through the carburetor's input valve and into the metering chamber as a result of the movement of the diaphragm.

Fuel Delivery: The fuel pump diaphragm pumps fuel into the carburetor, where it is ready to be combined with air and fed to the engine, in a steady and consistent flow.

Metering Diaphragm:

The metering diaphragm is another critical component of the carburetor, responsible for controlling the amount of fuel delivered to the engine based on varying engine demands.

Here's how it works:

Airflow and Pressure: As the engine runs, air flows through the carburetor, creating varying levels of air pressure within the carburetor's metering chamber.

The metering diaphragm is set up to respond to these variations in air pressure. The increase in airflow results in a decrease in pressure in the metering chamber when the engine requires more fuel, such as during acceleration or under heavy load.

The measuring diaphragm flexes inward in reaction to the decreased pressure. More gasoline may now flow from the carburetor's fuel bowl into the engine's intake airflow thanks to the flexing motion that opens the metering diaphragm's valve.

Control of the airfuel mixture: The metering diaphragm precisely controls the amount of fuel delivered to the airflow in order to adjust the airfuel mixture to the engine's needs under various operating situations.

The airfuel mixture is adjusted in accordance with the needs of the engine, whether it is idling, accelerating, or operating at full throttle, thanks to the cooperation of the fuel pump diaphragm and metering diaphragm. The compact twostroke chainsaw engine can function effectively and efficiently under a variety of operating situations thanks to this dynamic control.

I hope you have gained something from this video

Thank you

Craig Kirkman (Owner and Creator of The Repair Specialist Channel)

#ChainsawCarburetor

#DiaphragmOperation

#FuelPumpDiaphragm

#MeteringDiaphragm

#AirFuelMixture

#TwoStrokeEngine

#EngineEfficiency

#CarburetorComponents

#SmallEngine

#ChainsawMaintenance

#EnginePerformance

#FuelDeliverySystem

#CarburetorFunction

#AirPressureControl

#DynamicFuelSystem

#EngineTuning

#CarburetorRepair

#FuelFlow

#ChainsawOperation

#FuelMixtureControl