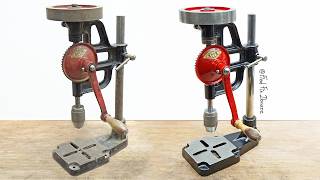

The 'REGULATEUR' - Vintage Centrifugal Drill Press Restoration

This time I am restoring an old bench drill. It was built from about 1905. The special feature is the centrifugal weights that automatically regulate the contact pressure. When the machine came on the market, this must have been a very big relief. At last, you no longer had to crank with one hand and regulate feed with the other; you had one hand free to control the workpiece.

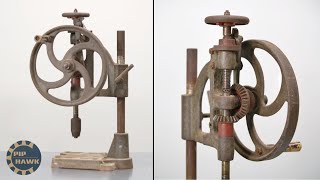

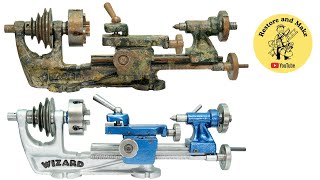

Restoration was quite a challenge. At first it looked like there was just some rust and patina. But then it became apparent that someone had thrown the whole machine into an electrolysis bath of copper. There was a layer of copper almost a millimeter thick everywhere. While there was no longer any rust, the copper had crawled everywhere and baked everything tightly together. So I couldn't salvage the drill chuck either and had to replace it with another antique drill chuck. Many parts had to be remade. A lot of work for my little lathe!

I tried to keep everything as true to the original as possible. But I allowed myself one small improvement. The machine had only a small sliding disk made of metal as bearing for the drilling spindle. It would run pretty rough with that. Here I added a small axial bearing, which ensures smooth and even running. But the bearing can also be easily removed again.

The test left me quite impressed. The drill runs very quietly, smoothly and powerfully. The automatic regulation works perfectly. The contact pressure remains stable until the end. Drilling in wood and steel was very easy. A wonderful piece of engineering history!

Lastly, I would like to thank Mr. Holger Paucke. He provided me with information from the mold archive of Arnz Flott AG and made the 1913 catalog available to me. This helped me a lot during the restoration. It is nice to see that the company that built the Regulateur under the name of ARNZ from 1905 is still building drilling machine today under the name of FLOTT.

Enjoy the video!

![1890s' Most Unnecessarily Complicated Apple Peeler [Restoration]](https://i.ytimg.com/vi/xrZiY3_HC5k/mqdefault.jpg)