Real-World Bearing Defect Diagnosis using Vibration Analysis

In this educational video from the RMS Reliability Training Institute (https://rmstraining.com), Stuart Walker provides a comprehensive, handson tutorial on how to diagnose a bearing defect through data collection, analysis, and inspection, identifying the root cause of the damaged bearing. See below for a timestamped summary.

In this video, you'll discover:

(0:15) Introduction to the thermal oxidizer unit at a chemical plant, which the team is set to inspect for a suspected vibration problem.

(0:55) Explanation of how the vibration route is loaded into the analyzer and data is collected from the combustion fan.

(4:07) Once back in the office, the collected data is transferred from the analyzer into the PC for further analysis.

(4:37) An exception report is run to identify any alarms that were triggered during the data collection phase.

(5:55) Presentation of the melter points plot that shows various parameters of the combustion fan.

(6:48) A look at the trend history that reveals increased levels of high frequency values, indicating a potential issue.

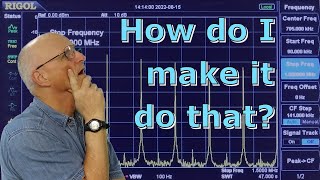

(9:06) Examination of the spectrum history and waveform, revealing a lot of highfrequency activity.

(10:07) Detailed analysis of the frequency spectrum and time waveform.

(11:23) Identification of nonsynchronous harmonics, indicating a bearing defect.

(12:25) Using the bearing numbers, potential issues are overlaid onto the analysis for further understanding.

Don't forget to like, comment, share, and subscribe for more valuable insights on machinery maintenance and asset reliability!

Visit RMS Reliability:

Website: https://rmsreliability.com

Training: https://rmstraining.com

Articles: https://rmsreliability.com/blog

♀ Connect on Social Media:

LinkedIn: / reliabilitymaintenancesolutionsltd

Twitter: / rms_ltd_uk

Facebook: / rmsreliability

Instagram: / rmsreliability

#VibrationAnalysis #BearingDefectDiagnosis #FaultDetection #ConditionMonitoring #MaintenanceEngineering #MechanicalEngineering #HandsOnTutorial #SpectralAnalysis #BearingFailure #IndustrialMaintenance #PredictiveMaintenance #EquipmentDiagnosis

⚠ Disclaimer: This video is for educational purposes only and is not intended as professional advice. Always consult with a qualified expert before making any decisions regarding machinery maintenance or asset reliability improvement.