What the difference between ISO 9001 and ISO 13485?

Introduction:

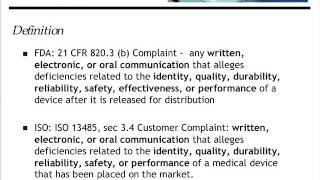

ISO (International Organization for Standardization) standards play a crucial role in ensuring organizations meet certain benchmarks when it comes to quality management, regardless of their industry. ISO 9001 is the most widely recognized standard worldwide, focusing on quality management systems (QMS) for general industries, while ISO 13485 is specific to the medical device industry.

ISO 9001 Quality Management Systems for General Industries:

ISO 9001 sets the foundation for quality management across various sectors, including manufacturing, services, technology, and more. The standard emphasizes customer satisfaction, process improvement, and continual enhancement of the QMS. Organizations that comply with ISO 9001 demonstrate their commitment to delivering consistent, highquality products and services.

Key Aspects of ISO 9001:

Customer Focus: Understanding and fulfilling customer needs and expectations are central to ISO 9001.

Process Approach: Emphasizing the importance of systematic processes for efficiency and effectiveness.

Continuous Improvement: Encouraging organizations to identify areas for enhancement and take corrective actions.

Leadership Involvement: Top management plays a critical role in driving quality initiatives.

RiskBased Thinking: Identifying and managing risks to prevent potential problems.

EvidenceBased Decision Making: Relying on data and information for decisionmaking processes.

ISO 13485 Quality Management Systems for the Medical Device Industry:

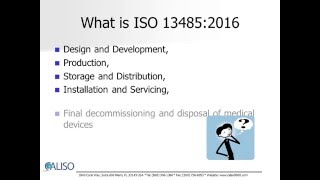

ISO 13485 is specifically tailored for organizations involved in the design, development, production, installation, and servicing of medical devices. Compliance with ISO 13485 ensures that medical device manufacturers adhere to stringent quality and safety standards, minimizing risks and ensuring patient safety.

Key Aspects of ISO 13485:

Regulatory Compliance: Meeting legal and regulatory requirements specific to the medical device industry.

Emphasis on Risk Management: Addressing potential risks associated with medical devices throughout the product lifecycle.

Validation and Verification: Thoroughly testing and validating products to ensure they meet intended requirements.

Focus on Traceability: Maintaining a clear and transparent record of product materials and processes.

Design and Development Control: Ensuring proper planning, validation, and verification of product designs.

Process Validation: Validating manufacturing processes to ensure consistent product quality.

Scope and Application:

One of the primary distinctions between ISO 9001 and ISO 13485 is their scope and application. ISO 9001 is a generic standard, applicable to organizations of all sizes and industries, while ISO 13485 specifically targets the medical device industry.

Certification:

While both standards are voluntary, organizations often seek certification to demonstrate their commitment to quality. ISO 9001 certification signifies a robust QMS for general industries, potentially enhancing customer trust and marketability. On the other hand, ISO 13485 certification is essential for medical device manufacturers as it is often a legal or regulatory requirement to market medical devices in many countries.

Benefits of Compliance:

ISO 9001 and ISO 13485 compliance bring several advantages to organizations:

Enhanced Customer Confidence: Compliance demonstrates a dedication to quality, enhancing customer trust.

Improved Efficiency: Both standards promote streamlined processes and reduced waste.

Access to International Markets: ISO certification can open doors to new markets and customers worldwide.

Risk Mitigation: Addressing risks and taking preventive actions leads to improved product safety and reliability.

In conclusion, ISO 9001 and ISO 13485 are both valuable quality management standards, but they cater to different industries with specific requirements. While ISO 9001 focuses on enhancing quality across general industries, ISO 13485 is tailored to meet the stringent demands of the medical device sector. Understanding these differences is crucial for organizations aiming to achieve compliance and establish a culture of quality within their respective industries.

If you found this video helpful, don't forget to like, share, and subscribe to our channel for more informative content on quality management systems and industryspecific standards. Thank you for watching!

*Connect With Us:*

www.patientguard.com

![Best ISO 13485:2016 Starter Video [For Medical Devices]](https://i.ytimg.com/vi/3i2gYGzopyY/mqdefault.jpg)