What is JACKSCREW and how it works - Translating Screw Jack and Rotating Screw Jack

• Find out more about our project:

https://jaescompany.com/elearning.php

• Here are some products installed by our technicians:

https://www.jaescompany.com/catalogo_...

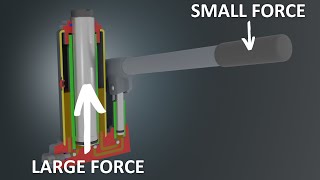

A Screw Jack also known as a Worm Screw Jack, is a device used to convert rotational motion into a “pushpull” linear motion. It utilises the property of a screw thread providing a mechanical advantage which means that it can be used to amplify force. The rotary movement can be supplied manually or thanks to the help of hydraulic or pneumatic motors. Or thanks to electric motors, like the induction motor!

In this video we will focus on the working principle of the worm screw jack.

We will see in detail the structure of its screw thread.

We will show the differences between the translating screw jack and the rotating screw jack.

And we will explain where the screw jack is used

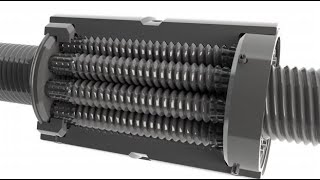

A worm screw is the essential feature of a screw jack.

Here we can distinguish its main diameters, the thread elements, the pitch which is the distance between two threads, and the thread angle.

We can notice that this type of screw is a helical structure used to convert between rotational and linear movement or force. This is the pitch of the helix, while this is the tilt angle of the helix.

In this section we can clearly see the angle of the helix that determines the number of teeth of the screw, which are called “cogs”.

Having a wide helix angle, the worm screw has a small number of cogs.

It is called “worm” screw because its rotary motion has the sole purpose of being transmitted, like in every gear wheels.

The worm screw meshes with a worm gear. This two elements are also called the worm screw and worm wheel. This arrangements can reduce rotational speed or transmit higher torque. Let us remember that the torque is the tendency of a force to cause or change the rotational motion of a body about an axis.

Worm screw and gear arrangement has a high transmission ratio, which depends on the thread angle of the screw and the number of teeth of the worm gear.

The screw transmits the rotary motion to the worm gear. Usually this motion can only be transmitted from the screw to the worm gear and not the other way around. However, there are some arrangements where the screw and the worm gear have such a thread angle that allows the worm gear to drive the screw.

The mechanical efficiency represents the measure of the effectiveness with which the mechanical components perform without losing energy. The “irreversibility” of the gear arrangement is inversely proportional to the efficiency. In fact, when the effciency is less than 50%, and when the helix angle is equal to or less than the angle of friction, the mechanism will be irreversible and it can only be driven by the worm screw.

The worm gear mechanism usually has low efficiency, that’s because there are many contact areas. Plus the sliding motion creates friction between the gears. For this reason screw jacks have a high wear rate.

To overcome this issue, special combination of steel and bronze are used during the production process, so that only the bronze parts of the worm gear mechanism can be replaced.

There are 2 types of screw jacks: the translating screw jack and the rotating screw jack...