Rubber Roller Manufacturing Process.

The rubber roller manufacturing process involves several steps. Here is a general overview of the process:

1. Rubber Mixing: The process begins with preparing the rubber compound. Natural or synthetic rubber is mixed with various additives such as curing agents, accelerators, fillers, and pigments. This mixing process takes place in special mixing machines.

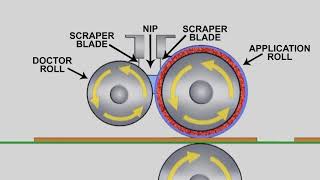

2. Roller Forming: The mixed rubber compound is then shaped into the desired roller form. This can be done through various methods such as extrusion, calendering, or molding. Extrusion involves forcing the rubber compound through a die to create a continuous shape, while calendering uses rollers to shape the rubber into sheets. Molding involves placing the rubber compound into a mold and applying heat and pressure to form the desired shape.

3. Curing: The formed rubber rollers are then cured to give them their final properties. Curing involves applying heat and pressure to the rollers in a curing press. The curing process allows the rubber to crosslink and harden, resulting in improved strength and durability. The time and temperature required for curing depend on the specific rubber compound used.

4. Grinding and Finishing: After curing, the rubber rollers may undergo grinding and finishing processes to achieve the desired dimensions and surface finish. Grinding removes any excess rubber and ensures precise dimensions. Finishing processes, such as polishing or coating, may be applied to enhance the roller's surface properties.

5. Quality Control: Throughout the manufacturing process, quality control measures are in place to ensure the rollers meet the required specifications. This includes dimensional checks, hardness testing, visual inspections, and other testing methods.

6. Packaging and Shipping: Once the rubber rollers pass the quality control checks, they are packaged and prepared for shipment to customers.

It's important to note that the specific manufacturing process may vary depending on the type and application of the rubber roller. Different industries, such as printing, paper processing, or industrial manufacturing, may have additional requirements or variations in the process.

#futianroller #rubberroller #rubbercoatedroller #rubbercoveredroller #RubberRollerManufacturing