Reversing Valves (RSES NATE Prep)

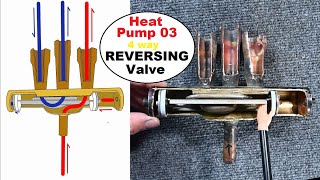

In this installment of RSES NATE Prep, Bryan covers reversing valves on heat pumps. He shows illustrations and diagrams to help you understand how they work.

Reversing valves, also known as fourway or changeover valves, allow heat pumps to switch from heating to cooling. Most systems will energize the reversing valve in cooling mode (usually via the orange wire and O terminal), though some manufacturers will energize the valve in heating mode. In doing so, the indoor evaporator becomes the condenser and vice versa. Instead of Y being the "cooling call," it merely energizes the contactor coil; O or B usually dictates heating or cooling.

A reversing valve consists of two pistons, a ported sliding block, and a pilot valve. The 24v solenoid activates a pilot valve that relies on discharge and suction pressure to shift the valve back and forth. A sliding block that looks like a canoe reroutes the refrigerant based on where it has been shifted. The common suction will always be at the bottom center of the reversing valve, and the common discharge will always be at the top of the reversing valve. Depending on the block position, the two lines on either side of the common suction could be suction or discharge lines. The reversing valve allows the direction of refrigerant to reverse while maintaining the same refrigerant piping.

You can only shift a reversing valve when the system is running and when the compressor is pumping sufficiently. Otherwise, the valve won't shift; it needs a pressure differential.

In cooling mode, the discharge gas goes to the outdoor unit. In heating mode, the discharge gas goes to the indoor unit. Even though the refrigerant moves in both directions, the liquid line remains the liquid line. As a result, we need to use a biflow filterdrier to filter the refrigerant in either direction. When we switch from cooling mode to heating mode, we want the refrigerant flow to bypass the cooling mode metering device and vice versa. Most heat pumps have two metering devices with check valves to allow refrigerants to bypass the metering device, though some also have TXVs with internal check valves, allowing flow in both directions. Some heat pumps also have pistons that can seat or unseat depending on the direction of flow.

Due to the increased likelihood of compressor flooding or slugging, some heat pumps have an accumulator to intercept liquid refrigerant before it reaches the compressor.

Visit RSES website here: https://www.rses.org/

Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/