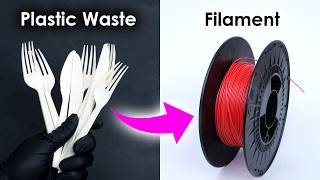

Recycling 3D Prints and Waste Plastic into Filament (PET u0026 PLA)

Transform your unwanted 3D prints and household plastics into ecofriendly 3D printer filament!

More Extrusion Info: https://www.DrDFlo.com/Extrusion.html

Filabot Recycling Lineup: https://www.filabot.com/products/recy...

Shredii: https://actionbox.ca/products/shredii5

DFlo's Amazon Store: https://www.amazon.com/shop/dr.dflo

Follow Dr. DFlo on the Gram: / dr.dflo

Description: Welcome to Part 2 of Dr. DFlo’s plastic extrusion series. If you haven’t already, be sure to check out Part 1 ( • How to Extrude 3D Printer Filament (B... ), where a variety of NEW materials are extruded into 3D printer filament. In this video, we will recycle unwanted 3D prints and plastic items found around the house into filament.

The first step in this process is to grind up old parts and empty containers with a shredder/granulator. You'll discover that groundup plastic isn't the same as new pellets; it's lighter and requires some extra processing before it can be melting and drawn out as a constant diameter fiber. These extra steps include a 3 mm extrusion followed by pelletizing. Ultimately, we end up with a 100% recycled feedstock that can be used for producing 3D printer filament or in any thermoplastic processing equipment (e.g., injection molding).

#recycling #filament #3dprinting

Table of Contents:

00:00 Intro

01:29 Recycling 3D Prints

01:58 Shredding (Reclaimer)

07:55 Extruding regrind

14:38 Pelletizing

17:40 Degradation

20:10 ReExtruding

21:15 Economics

24:00 Recycling Commodity Plastics

27:10 Pultrusion

29:00 Shredding PET Bottles

30:35 PET Extrusion Challenges

35:15 Extruding PET Flakes