pump cavitation and net positive suction head

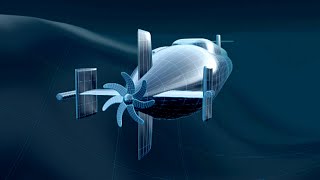

If you are dealing with a centrifugal pump. You have heard of net positive suction head and cavitation. This video will explain what is npsh. Why Net positive suction head is so important for pumps and how to determine the net positive suction head is also explained in this video.

As per hydraulic institute standard, npsh is the liquid energy, above the vapor pressure, at the pump inlet. Each pump requires some minimum absolute pressure at the pump inlet to avoid cavitation in the pump.

This minimum absolute pressure or absolute suction head in terms of the height of the liquid column, at the pump inlet, is known as net positive suction head. if the suction head at pump inlet drops below vapor pressure. The fluid will evaporate and generates small vapor bubbles. These bubbles carried along with the fluid, and collapse instantly when they get into areas of higher pressure. This will result in excessive noise and vibration, due to the collapse of vapor bubbles. it will damage the pump impeller and pump casing due to erosion. This whole phenomenon is known as cavitation. This minimum absolute suction head, at the pump inlet, which is above the vapor pressure represents the available net positive suction head.

To avoid cavitation, this absolute head at the pump inlet must be greater than vapor pressure. So if we subtract vapor pressure from this absolute inlet head. It must be always a positive term. And known as Net Positive Suction Head Available.

Till now, we have understood what is net positive suction head available. But how much net positive suction head required for a pump is calculated by testing a pump.

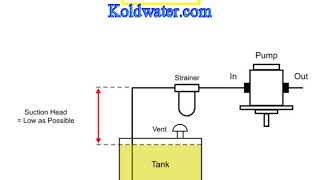

The most common method. Often known as the constant flow method is used to determine the npshr. In this method, the pump discharge valve is kept at the fixed open position. so that pump flow remains constant. However, the pump suction valve is throttled. Due to throttling of the suction valve, pump inlet pressure reduces. But, the pump developed head, and flow remains constant. Until a point where inlet pressure reduces to vapor pressure.

After each throttling of the suction valve, the Pump manufacturer notes down the Total head developed by the pump, and Net Positive Suction Head Available. The Pump manufacturer repeats this step, Until a point where the total developed head decreases by at least 3 percent. The net positive suction head corresponding to the 3% drop in pump developed head is known as NPSH3 or net positive suction head required.

net positive suction head available

net positive suction head

the net positive suction head required

NPSH of centrifugal pump

NPSH calculation example

NPSH explanation

NPSH available and NPSH required

NPSH calculation

NPSHA and NPSHR

NPSH and cavitation

NPSH animation

NPSH definition

pump cavitation

cavitation explanation

cavitation

pump cavitation

cavitation in pump

cavitation in centrifugal pump

cavitation in fluid mechanics

cavitation in centrifugal pump animation

cavitation and vapor pressure

net positive suction head for centrifugal pump

cavitation in centrifugal pump

NPSH of pump

what is cavitation

cavitation

#pump cavitation

#net positive suction head

#NPSH

#NPSHR

#NPSHA

npsh margin 6:15 to 6:35

introduction 0:02 to 0:34

npsh definition 0:34 to 1:38

what is cavitation 1:40 to 2:15

pump developed head 1:02 to 1:39

how to calculate net positive suction head available 2:29 to 4:33

how to calculate net positive suction head required 4:39 to 6:12

NPSH3 4:39 to 6:12

how to perform npsh test 4:46 to 6:10

application of specicific speed watch this • Unlocking Pump Efficiency: A Comprehe...

How to select pump speed: A complete guide as per Hydraulic Institute standards watch this • Unlock Maximum Efficiency: Mastering ...