Injection Molding - Undercuts (How to Avoid and Design)

Learn what an undercut in injection molding is and how to design your part avoiding undercuts. We'll demonstrate how to redesign a part with an undercut in Fusion 360 using a shutoff.

Subscribe for more

/ @protolabsmfg

00:00 Intro

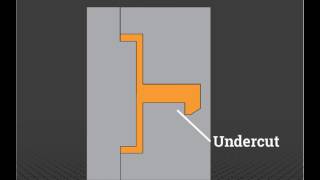

00:23 Learn what an undercut in injection molding is. We'll demonstrate how an undercut makes it difficult for a part to be ejected from the mold.

00:50 We'll discuss the 4 main ways to avoid an undercut in injection molding.

01:01 Shutoffs explained. You'll learn how removing material under the undercut can help the part eject better from the mold.

01:26 Moving the parting line explained. This is the easiest way to avoid an undercut in injection molding.

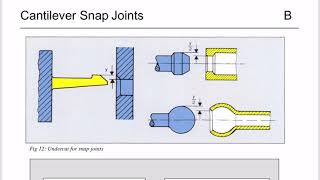

01:42 Bumpoffs explained. Learn when and how to use a bumpoff for undercuts.

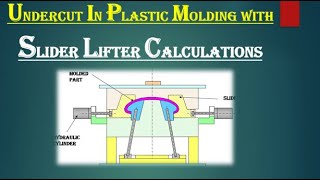

02:16 Sliding sideactions and cores explained. Learn to use sideactions when an undercut can't be avoided.

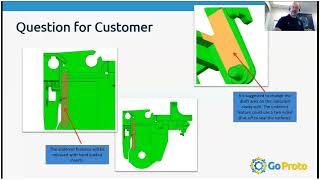

02:47 We'll remodel a part with a snapfit feature and undercut in Fusion 360. You'll learn how to create a shutoff by making a cut out under the snapfit feature. Finally, we'll add a draft angle to the design.

FREE injection molding manufacturing and design guide: http://3dhu.bs/zeBYlu

Protolabs is the fastest and most comprehensive digital manufacturing service in the world, combining inhouse quickturn factories and premium manufacturing partners at Protolabs Network. Users can easily upload their design, instantly receive a quote, and start production at the click of a button.

Order custom parts online today: https://identity.protolabs.com/

/ protolabs

Facebook: / protolabs

Instagram: / protolabsmfg

/ protolabs