Industrial Fan Types Energy Consumption and the Fan Static Efficiency Calculation

Visit https://airprofan.com/'>https://airprofan.com/ Call 7153653267 Email [email protected]

Trying to determine the right industrial fan type for your application and expected energy consumption? Just like economics, it depends.

Key elements in fan selection for static efficiency and reliable operation include what the fan is processing from clean air to mild particulate to highly abrasive materials, as well as volume and static pressure. Senior Application Engineer Chet White explains the factors that determine which industrial fan type is optimal and how much energy it will consume in this 12minute whiteboard tutorial.

Full Transcript:

How much energy your fan consumes and which type is right depend on the application.

6 common fan types:

Open radial with radial blades, also called paddlewheels (front and side views)

Shrouded radial with a backplate, a shroud on the front, and radial blades

Industrial exhaust air handling with backwardly inclined blades that slowly build velocity on the face of the blade from wider to narrower

Radial tip with forwardcurved (cupped) blades to wick particles off blades

Backward inclined with a wider inlet

Backwardcurved

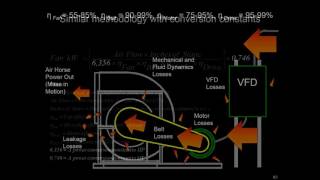

We calculate energy consumption based on required performance. If the process is dirty or unknown, the safest pick is an open paddlewheel. The more abrasion the quicker it will fail, but this fan can move essentially anything. For example, we’d need a 2530 HP driver to move this type of wheel to do 10,000 CFM at 10 inches with max static efficiency at roughly 63 percent. Now let’s apply that to our most efficient wheel and a clean process. Using a backwardcurved fan, we can achieve 80 percent static efficiency with a 20 HP motor to move the exact same 10,000 cfm at 10 inches of static pressure that we just discussed.

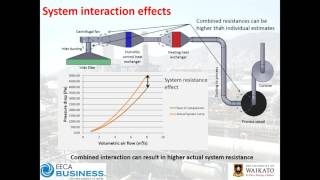

For clean applications, the higher the volume to pressure ratio, the more likely you can use a highefficiency fan like backward inclined, backward curved, or maybe an airfoil. Conversely, if static pressure is really high and volume is really low, smallerwidth fan wheels are required. The space between the blades must be much tighter, with a larger diameter fan, decreasing efficiency.

Even with a clean application, low volume to static pressure ratio like 100 inches of static pressure at 5000 cfm forces a larger diameter very narrow width radial blade. In this case, energy consumption would be somewhere in the 67 percent static efficiency range. But you can easily move 50,000 cfm at 10 inches with a higher efficiency wheel. You’d then expect to apply max 7780 percent static efficiency to determine needed horsepower.

The other thing to consider is what you’re moving with the blades. If it’s clean air, all of these wheels are on the board you can pick any of them.

For mildly contaminated air, higherefficiency fans can work, but for extra safety, radial tipped and industrial exhaust air handling are better suited. Here’s why. These blades are backwardly inclined and contact the airstream on the inner part of the blade. Moving out on a backward incline, gas will gradually release from the blade without much friction. That’s great for efficiency, but it’s bad if you have particulates that can build up, affecting fan balance. Using high efficiency fans to move material means more maintenance.

These are safer for mild particulate because of the nature of the blade profile and the way the wheel narrows towards the outer end. Radial tip and industrial exhaust air handling styles are more equipped to shed the material off the end of the blade compared to a constant profile of width. In saturated gas applications like scrubbers that have some wetness in the air you’re moving, radial tip and industrial exhaust air handling are safer for the same reasons.

For heavier material handling of things like corn husks, manure, paper trim, aluminum chunks etc., the only choice is a radial paddlewheel. The blades extend from the outside all the way to the hub, so there’s no gap like you’d get in an industrial exhaust air handling or radial tip. That’s good, because if you had a gap, the inside edge would wear out quickly and you could destroy the fan wheel pretty fast. The more abrasive the material gets, the thicker you can make the material along the blade.

In summary, how much energy the fan consumes varies greatly by application and which style wheel you have. So review your application, see what you’re moving through the fan, and see if you can increase efficiency from 67 up to 80 percent, for example. If it’s just moving clean air, why not gain that extra efficiency? Your energy consumption is dependent on the style of fan in your system.

VISIT OUR WEBSITE:

https://airprofan.com/'>https://airprofan.com/

SUBSCRIBE TO OUR CHANNEL FOR OTHER VIDEO TIPS:

https://bit.ly/AirProSubscribe

SUBSCRIBE TO OUR EMAIL LIST:

https://airprofan.com/'>https://airprofan.com/contact/

LET’S CONNECT!

Email: [email protected]

LinkedIn: / airprofanandblower