How to Use Mechanical Gear Pullers

Available in Australia: https://bit.ly/2Xk9ado NZ: https://bit.ly/2Nm3YBa

Whether it’s a pulley, brake rotor, internal bearing, external bearing, or a bearing race – Toledo makes removing it easy; with an extensive range of puller kits.

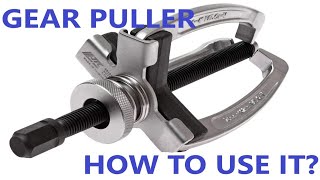

To cover the widest variety of jobs, you’ll certainly want a twin and triple leg puller set in your kit. Toledo manufactures these in three sizes. The smallest being 75mm, the largest at 150mm– with a 100mm kit in the middle. These tools come assembled as a 2 leg puller – with an extra leg and a triple head for expansion to 3 legs when necessary. Supplied in an EVA foam cutout, they store neatly in the toolbox.

Whether set up as twin or triple leg, these are suitable for most internal and external pulling applications. To use one of these, simply position the jaws around the edge of the part to be pulled; and wind the forcing screw inward until it makes contact with the shaft. Reposition the legs if necessary, then tighten the forcing screw until the part is removed.

For pulling smaller internal bearings such as spigot bearings; or motorcycle wheel bearings; make sure a Toledo Pilot Bearing Puller is part of your kit.

Supplied in a blow mould storage case, it’s time to break this tool out when things look tricky. The small jaws of this puller slip through the centre of the bearing, and are locked in place by screwing the handle to open the jaws. Once you have positioned the legs on a stable area on the outside of the bearing, you just hold the handle still; and tighten the nut down with a 21mm spanner.

If you have access to threaded holes in a gear or pulley; the Harmonic Balancer Puller Set may be your best option.

With 46 pieces in the set, there’s everything you need for all types of pulleys. The main components are the crows foot, forcing screw, and end adaptors. The massive selection of bolts ensure that every hole size and thread pattern is accounted for. Once you have found the correct bolt size; wind the forcing screw through the crows foot, attach the end adaptor and thread the bolts through the crows foot and into the pulley.

Now watch your gear or pulley slowly slide free as you tighten the forcing screw.

Selected power steering pumps are designed for the pulley to be removed in a different manner. The Toledo Power Steering Pump Kit will have the pulley off, and the new one on in no time. Here’s how it works.

Start off by choosing a forcing screw. The thread does not need to match that of the power steering pump, as it will only push against the shaft. Wind the large centre nut all the way down to the pulley, and then slip the two halves of the jaw cup over the centre nut ensuring they secure around the flange on your pulley. Slide the retaining ring over these to hold them in place. Now tighten down the forcing screw to remove the pulley.

Select the other piece in the kit to reinstall the pulley. The forcing screw thread DOES need to match the power steering pump for this. Just thread the forcing screw into the shaft, use a wrench to hold the forcing screw steady; and tighten the flange nut to press the pulley into place.

For those doing a lot of mechanical work, Toledo’s range of pulling tools is invaluable. Add them to your kit today, and conquer every job.

Supercheap Auto Website: http://bit.ly/1FpfKkw NZ: http://bit.ly/2rK6Lg5

YouTube Channel: http://bit.ly/2sjZ92q

Like us on Facebook: http://bit.ly/1Ry7HuN

Supercheap Auto Blog: http://bit.ly/2skbVOE

Watch our latest and greatest television ads, Check out our how to videos, product videos or learn how to check it!

![WHAT A DEAL?! ICON 22piece Long Jaw Puller Set [LJP22]](https://i.ytimg.com/vi/YQhfQAuE57o/mqdefault.jpg)