How to Use and Read a Digital Caliper

Welcome to my channel, Matt's Metalworking. Please don't forget to hit that LIKE button and SUBSCRIBE for future videos. My name is Matt and I produce metalworking relating videos which can include fabrication, machining, milling, turning, welding, tool tutorials, etc.

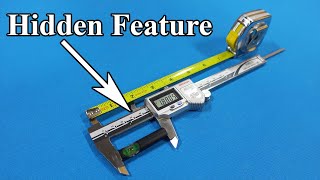

In this video, I will be showing you how to use and read a digital caliper. A caliper can take measurements in four different was using the outside jaws, inside jaws, depth probe, and using the step.

A digital caliper is by far the easiest to use and read, can operate in both imperial and metric measurements, however it is the most expensive to purchase and does require electronic upkeep being battery replacement. Just like any precision measuring equipment, this should never be dropped, always kept clean and free of any foreign contaminants, and checked periodically to ensure it’s accuracy.

To go over the parts of the caliper.

First is the outside jaws which are used to measure the outside diameter, length, width, or thickness of an object.

Next is the inside jaws used to measure the inside width of a slot, groove, or hole or the inside diameter of a bore.

The depth probe or rod used to measure a groove, slot, step, or hole.

The beam or sometimes referred to as a bar is the frame of the caliper that is stationary and houses the depth probe.

A measuring scale used to determine the measurement, in this case only really used as a visual reference as the digital display provides the full reading.

Here is the fine adjustment thumb wheel to achieve accuracy when setting up or adjusting the feel or drag when measuring an object.

Then the thumb grip for quick or large adjustments.

A thumb screw lock to hold the caliper measurement in place.

The digital which shows the current measurement both in imperial and metric reading. The buttons around the display are used to turn the caliper on or off, zero the measurement, and to switch between measuring systems.

Battery locations and access door types may vary, just to give you an idea for this one. The door simply slides open and the battery sits in place.

Always ensure the surface you are measuring is clean of any surface imperfections or dirt. Make sure the measuring points on the caliper is clean as this can affect the accuracy of our readings. Close the jaws and zero the digital readout by pressing the button close to the display.

Using the outside jaws to take the first measurement using the imperial measurement from the scrap piece of aluminum. I’ll show metric in a moment.

We need a mild drag on the surface where the part is still movable, yet we can still feel some surface drag. Apply the lock if needed and take the reading. This particular caliper will provide accuracy up to 5/10s of a thou or 0.0005. Our first measurement is 0.5755 or 575 thousandths or thou and 5/10s of an inch.

Next using the step measurement. Close the caliper, make sure the readout is zeroed. You may need to open the jaws slightly to help the measuring surfaces rest on the edge. Then push the caliper into place. Just to give you a view of how the step measurement sits with reference to the part.

Apply the lock if needed. Our final measurement is 0.521 or 521 thousandths of an inch. Now switching over to metric, this can be done very easily with the press of a button. Again we need to close the caliper and make sure the readout is zeroed. Using the depth probe this time to measure the depth of this threaded hole.

Extend the probe long enough so it’s able to bottom out and we still have some added length which allows the measuring surface on the beam to close against the object.

Just to give you a reference as to how far the probe can reach inside the threaded hole. This may be limited as the probe may sometimes too large to fit in a small hole.

This gives us a final measurement of 25.59mm.

And finally using the inside jaws.

Ensuring the measuring surfaces are always clean on both the part and caliper. Insert the jaws, this time around I am measuring a slot. There should be a mild surface drag on the object, this does take some practice to get used to the feel. Then take the reading. Here our measurement is 33.13mm.

When using this type of caliper, we can even easily switch between measuring systems. Imperial to metric or metric to imperial with the press of a button, so no calculations or conversions are required. While a digital caliper does make taking measurements extremely efficient, you should still learn the basics with a vernier caliper.

This concludes the rest of my video, if you have enjoyed it, please leave a comment below and throw a like my way. Don’t forget to subscribe for more metalworking videos, thanks for watching.

![YOU NEED THIS! How To Use Digital Calipers [Dial and Vernier Too]](https://i.ytimg.com/vi/ohGi7yDbnEo/mqdefault.jpg)