FiTech - Hanging idle

An Idle Air Control (IAC) stepper motor valve is used to open or close a passage in small increments (called “Steps”) that adjusts the amount of AIR going through the throttle. The fuel calculation automatically senses the extra air and AFR, so there’s extra torque produced at idle to increase idle speed or decrease idle speed if the RPM doesn’t match the Target Idle RPM. The amount of steps needed is also learned, in order to improve the idle control.

Warm Idle Speed = This is the Target Idle RPM for when the engine temperature reaches 170 degrees Fahrenheit.

Reset Idle Learn = The Idle Air Learning can be reset to a default value (16 steps) – by setting this control value to 1, and turning the key off and waiting for the system to completely power down. This can be done if the IAC learned incorrect values from an improper throttle adjustment, or other situation that caused the learning to be wrong.

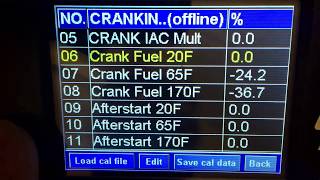

Idle Learn MAX = This is the maximum number of steps that can be learned up. There is a default base table that is used to automatically increase the IAC when cold. There are also 3 learn values for idle air: 20F, 65F, and 170F – this can help the cold engine idle be correct.

Idle Learn MIN = This is the number of steps that can the learning can learn in the closed direction from the base default table.

Loop Rate UP = The IAC uses a PID (actually just PI) closed loop control that adjusts the steps to achieve the desired idle speed. This value controls how quickly it can open the IAC in response to a lower RPM, using the “I” (integrator) of the PID.

Loop Rate Down = The IAC uses a PID (actually just PI) closed loop control that adjusts the steps to achieve the desired idle speed. This value controls how quickly it can close the IAC in response to a higher RPM, using the “I” (integrator) of the PID.

Fan RPM Adder = When the electric fan(s) is(are) turned on, the RPM can be increased by this amount to help both the coolant flow and the alternator speed to generate more voltage for the electrical system.

Fan Idle Steps = When the electric fan(s) is(are) turned on, the RPM can be increased to help both the coolant flow and the alternator speed to generate more voltage for the electrical system. This adjusts how many IAC steps are automatically added when the fan is on so that the loop and learning don’t need to do the work.

Decel Open IAC = When the throttle is opened, the IAC is also opened by several steps in preparation for when the throttle closes. This open IAC helps reduce engine braking during deceleration which can give a smoother drive feeling. However, too much can cause the RPM to jump a bit too much when the throttle is cracked open, or cause the engine to have positive torque for a moment after the throttle is closed.

Decel RPM Decay = When the throttle is closed, and the engine is returning to idle speeds, the Idle Closed loop will use Target RPM to control the speed during that period. The Target RPM will decay to the normal idle speed in a controlled manner. A smaller “Decel RPM Decay” value will be SLOWER.

Decel IAC Decay = When the throttle is closed, and the engine is returning to idle speeds, the “Decel Open IAC” steps will need to be removed in a manner that nearly matches the “Decel RPM Decay” of the Target RPM. This value is the fraction of a step that is decayed per 100 milliseconds (10 times per second).

CRANK IAC = Cranking needs extra air to help the engine spin to a higher RPM and to generate very full cylinders for maximum power to fire up the engine against the cold oil. However, at warm engines, the thin oil and easy combustion doesn’t need as much air to achieve a successful start, and too much will cause a very large flare of the RPMs just after starting.

![Running Rich at High VS Low RPM [HPA Q&A]](https://i.ytimg.com/vi/AZ1JtNKt7PA/mqdefault.jpg)