Coupling ! Types ! Applications ! Design ! Selection ! Animated tutorial

Know about mechanical couplings. Tutorial.In mechanical system coupling can be defined as a kind of linkage between two rotating shafts which joins driving and driven shafts together. The joint between two shafts may be permanent or temporary. In simple words we can say that coupling is used to join input and output shafts in any power transmission system such as in machine tools gear box shaft is connected to the input engine shaft by means of coupling; engine shaft with pump or compressor shafts etc. The function of the coupling is almost same as the clutches but clutches are temporary joint while the coupling joints are permanent connection.

According to the requirement and functions different types of coupling are used. The basic features of the different types of coupling are almost same which are given as follow:

1. Power Transmission

2. Join misaligned shafts

3. Reduce shocks and vibration

4. Easily to assemble and disengage

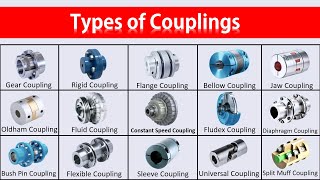

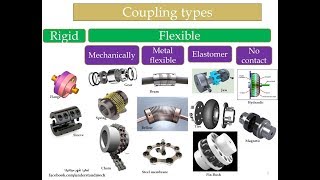

Types of Couplings:

1. Oldham’s Coupling:

Oldham’s coupling is used to connect the two parallel shafts when some eccentricity is present between two rotating shafts. In this the two misaligned shafts have disc shape flanges with rectangular slot at the middle. Both the flanges have slot cut which is at right angle to each other. In between two shaft a circular disc assembled having tongue on both side at right angle to fit between the slots of flanges. When shafts rotate then the tongue of the flanges slides into the recess of the flanges of the shafts. The middle disc rotates about its center but both the misaligned shafts rotate their own axis by means of sliding tongue into the grooves which results the center of the middle disc traces a circular orbit. A spring is required to remove the backlash of this running coupling.

2. Hook’s Coupling:

This is also known as hook’s joint, universal joint or coupling. It is called universal joint because it can able to joint two shafts having intersecting axes. It is used to joint connect two nonparallel and intersecting shafts which has some angular misalignment. The input and output shafts are connected using hook’s joint. The input driving shaft rotates at a uniform angular speed while the driven shaft rotates with varying angular speed i.e. both shafts have different angular speed. Both the shafts rotate in fixed bearing and have a fork at the end. Each fork has four ends and sides which are connected by center piece.

3. Double Hook’s coupling:

As name implies a double hook joint has two hook’s joint or universal joint which are connected by means of an intermediate shaft.

4. Rigid Coupling:

Rigid coupling is used where the axes of both the shafts are collinear. Rigid couplings are simple and less costly, but the major drawback of this type of coupling is that they cannot tolerate any kind of small misalignment between the axis of the shafts. Different types of coupling come under this category some are them are as follow:

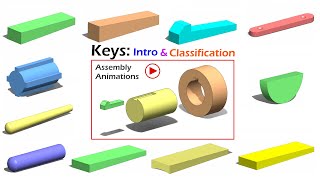

a.) Muff coupling:

This coupling also known as sleeve coupling because it has sleeve or a kind of hollow cylinder. The driven and driving shafts are joined in the sleeve by means of a key. Generally sunk key is used in muff coupling which makes it simplest coupling among all. The force transformation takes place from driving shaft to key then from key to sleeve and then to the driven shaft by means of key. Shearing force between the key and shaft is responsible for the power transmission.

b.) Clamp coupling:

Clamp coupling is the modified form of the muff coupling and also known as split muff coupling i.e. it has sleeve which is divided into the two half that’s why it is known as split muff coupling. The twosplit portion of the sleeve are clamped together using nuts and bolts. Both the shafts tightened together into the clamps, 4 or 8 nuts are used to tight the shaft into the split muffs.

c.) Flange coupling:

As name implies flange coupling has flanges for the joining of both the shafts. It is another type of rigid coupling so all the conditions are also applicable here like proper alignment of both the shafts and connection should not have any kind of vibrations and jerks.

5. Flexible coupling:

This is another category of coupling. As name suggest it has flexible connection between the input and the output shaft because it is very difficult to make a proper aligned connection between the two mating shafts and there are various reasons for the misalignment between the two shafts such as deflection of shafts, thermal expansions etc. so to remove all such causes flexible coupling comes into the play.