Chainsaw beam guide from wood (DIY mini mill)

Videos in this series~

(part 1) Chainsaw beam guide from wood

► • Chainsaw beam guide from wood (DIY mi...

(part 2) DIY Chainsaw Mini Mill Counterbalance:

► • DIY Chainsaw Mini Mill Counterbalance

(part 3 ) DIY Chainsaw Mini Mill Quick Clamp:

► • DIY Chainsaw Mini Mill Quick Clamp

(part 4) Log Prep & Procedure for DIY Chainsaw Mini Mill:

► • DIY Chainsaw Mini Mill Log Prep & Pro...

Chapters:

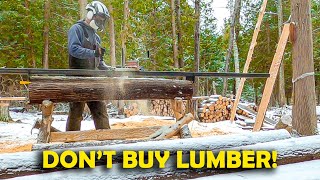

0:00 ►Useful introduction

2:49 ►Dimensions of jig

3:40 ►Installing jig

8:57 ►Limitations

11:29 ►Milling

20:25 ►Finishing up

After watching a ton of footage for this project, and after having spent a fair amount of time both thinking about this thing and playing around with it, I've reached a few conclusions. First of all, don't buy one of these; make one. The design shown in this video is solid. A steel one will perform no better, and it'll just be heavier. The limits in its performance come down to user error and/or application, not from any shortcomings in the gizmo itself.

Getting it straight: my earlier cuts would tend to allow the weight of the saw to slightly plunge the nose of the bar sideways, which resulted in a beam that was a little wider at the top. You can see this in the footage by looking at the uneven gap between the jig's 2x4 and the guide rail. Noted—and no big deal—but let's think about some ways to improve. One way is to just use feel: consistency follows from practice. Another way would be to introduce a counterweight, and I did consider that, but after toting it around for a day I've ruled the idea out. Right now, the best idea I have to offer is to add a slot/key feature. Imagine a removable pin, probably made of highdensity plastic, that would insert through the jig and into a groove (dado) that had been cut on the outside face of the guide rail. This pin would act as a training wheel; it would ride along and prevent those occasional pauses and slips that cause gouges, and it would train the user to compensate against the weight of the saw.

Note about paste wax:

There have been tons of comments suggesting to lower friction against the guide board by using a lubricant. Although I didn't mention it in the video, I did use white bar soap before cutting. However, this is really not necessary; like, really, really, not necessary. The speed of the jig in use is almost 0, and the chainsaw's vibration keeps it from ever becoming close to stuck. Far more important is to ensure that both the board and the jig have been properly sized and sanded.

...

FloweringElbow has a great set of vids on chainsaw milling, not to mention a great channel. This video alone should get you hooked:

► • Why DIY Chainsaw Mill BEATS Band Mill...