Building a Pneumatic Press : a DIY Replacement for a Toggle Press

After using a manual toggle press to press fit thousands of bearings, I decided it was time to switch to something a little more automated. I put together a pneumatic press with a few aluminum plates, a cylinder, valve, and some hardware and it's working great so far.

The original Schmidt toggle press was a model 17R.

Here are the parts used in the build:

McMaster Carr Part Numbers and Descriptions:

91423A220 FineThread MediumStrength Steel Hex Nut Class 8, M18 x 1.50 mm Thread

98861A100 LowStrength Steel Threaded Rod M12 x 1.75 mm Thread Size, 1 M Long

98861A120 LowStrength Steel Threaded Rod M16 x 2 mm Thread Size, 1 M Long

90591A220 ZincPlated Steel Hex Nut MediumStrength, Class 8, M16 x 2 mm Thread

91166A310 ZincPlated Steel Washer for M16 Screw Size, 17 mm ID, 30 mm OD

Spring Return Hand Valve from HQCTools.com

5/2 Way Hand Pull Valve with Spring Return, 1/4″ NPT 4H21008S

Pneumatic Components from AutomationDirect.com

PU8MBLU100 NITRA pneumatic tubing, 8mm outside diameter

MS51614N NITRA pneumatic pushtoconnect fitting, male, 5/16in (8mm) tube to 1/4in NPT

SBC18N Exhaust Silencers (I used some Festo Silencers I had on hand, not these)

UY8M NITRA pneumatic pushtoconnect fitting, union Y 5/16(8mm)

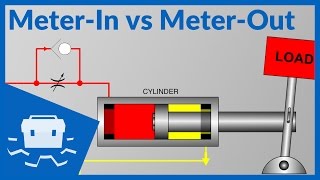

FVR8M38G Flow Controls (I used Festo again which are expensive). If you use the meterout version you only need one of these on the lower port and can use 3/8 BSPP/G quick connect fittings for the upper two ports).

Two Stage 100mm bore Cylinder from Aliexpress ( https://www.aliexpress.com/item/40000... )

Model should be SDAT 100x25x0 for $112+.